A data center is a huge set of tools, computers, equipment, and wires, all working simultaneously to keep data safe and manage the operations of the company. All of these operating at the same time means a lot of heat and possible challenges. To prevent overheating and potentially hazardous encounters, its vital to maintain airflow in the facility. Maintaining proper airflow in a data center might not seem like a big deal at first glance, but it’s a cornerstone of efficient operations and equipment longevity. Imagine running a marathon in a room with no ventilation—that’s how servers feel when airflow is neglected. A well-designed data center airflow management strategy ensures that equipment stays cool, runs efficiently, and avoids costly downtime.

That’s exactly what were going to discuss in this article of Danacloud: data center airflow management strategy, what it means, and how are the best practices for doing it.

What does data center airflow mean?

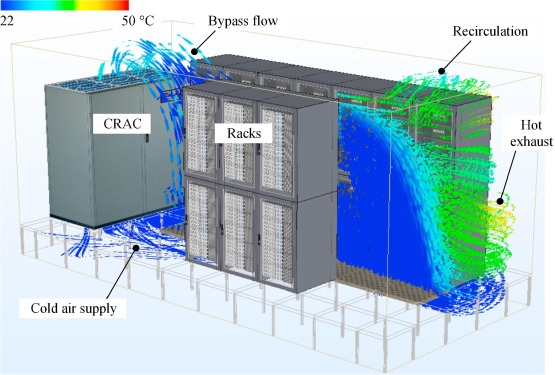

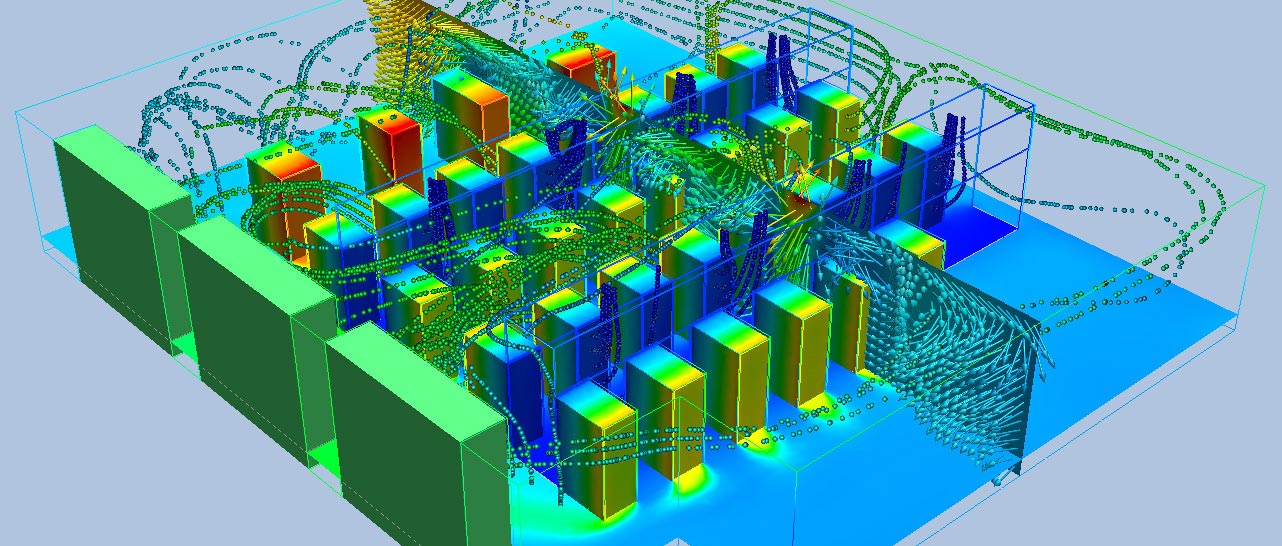

Data center airflow refers to the movement and management of air within a data center to regulate temperature and ensure efficient cooling of servers and equipment. Proper airflow prevents hotspots, minimizes energy waste, and maintains optimal performance by ensuring that cold air reaches hardware while warm air is effectively removed.

Efficient airflow design involves techniques like hot aisle/cold aisle containment, which separates cool intake air from heated exhaust air, and the use of advanced cooling systems like CRAC units or liquid cooling.

For instance, a poorly managed airflow setup can lead to overheating, while a well-designed system can significantly reduce power consumption and operating costs. Effective airflow is a cornerstone of sustainable and reliable data center operations.

5 tips for building a data center airflow management strategy

Implementing a robust data center airflow management strategy is essential for maintaining efficiency, lowering operational costs, and ensuring reliable system performance. Effective airflow management ensures that hot and cold air remain separate, enabling optimized cooling and energy use. Below are five detailed tips to help build a strong strategy:

Here’s a table summarizing the 5 tips for building a data center airflow management strategy:

| Tip | Description | Benefit |

|---|---|---|

| 1. Realize Hot Aisle/Cold Aisle Configuration | Arrange server racks so that intake sides face a cold aisle, and exhaust sides face a hot aisle. Use barriers to isolate airflow further. | Improves energy efficiency and reduces cooling costs by 20-30%. Prevents warm air recirculation into equipment intakes. |

| 2. Properly Set Up Server Cabinets | Align server cabinets with airflow principles, ensuring intakes face the cold aisle and exhausts direct heat to the hot aisle. Keep cables organized and clear for unobstructed airflow. | Reduces overheating risks, improves system efficiency, and ensures optimal airflow. |

| 3. Install Blanking Panels in Unused Space | Seal empty rack spaces with blanking panels to prevent cool air from escaping and mixing with hot exhaust. | Enhances cooling efficiency, lowers cooling requirements, and maintains optimal thermal conditions. |

| 4. Use Expandable Filler Panels When Racks Are Removed | Use expandable filler panels to close gaps left by removed racks, ensuring cold air flows properly to active servers while hot air is expelled. | Prevents airflow disruptions, maintains effective cooling, and ensures energy efficiency in temporary configurations. |

| 5. Monitor Temperature and Identify Hot Spots with DCIM | Utilize DCIM software for real-time temperature and airflow monitoring to identify hot spots and problematic areas. | Provides proactive insights for adjusting airflow, improving cooling efficiency, and preventing thermal issues. |

1. Realize Hot Aisle/Cold Aisle Configuration

Creating a hot aisle/cold aisle layout involves arranging server racks so that intake sides face a cold aisle while exhaust sides face a hot aisle. This setup prevents warm air from recirculating into equipment intakes. Adding barriers like containment systems further isolates airflow, significantly improving energy efficiency. For example, implementing this configuration can reduce cooling costs by 20-30%, making it both effective and cost-saving.

2. Properly Set Up Server Cabinets

Position server cabinets to align with airflow design principles. Ensure all equipment intakes face the cold aisle, while exhausts direct heat toward the hot aisle. Secure cable management to avoid airflow obstructions and keep pathways clear for maximum efficiency. Misaligned cabinets disrupt airflow, leading to overheating risks and inefficiencies.

Read more: What Is Data Center Consolidation?

3. Install Blanking Panels in Unused Space

Blanking panels are essential for sealing empty rack spaces, preventing cool air from escaping and mixing with hot exhaust. This targeted airflow reduces cooling inefficiencies. Studies show that installing blanking panels in unused rack spaces can lower cooling requirements and improve overall thermal conditions significantly.

4. Use Expandable Filler Panels When Racks Are Removed

Temporary rack removal often leaves gaps that disrupt airflow. Expandable filler panels close these gaps, ensuring cold air is directed toward active servers while hot air is expelled properly. This solution is cost-effective and prevents short-term disruptions from escalating into major cooling inefficiencies.

5. Monitor Temperature and Identify Hot Spots with DCIM

DCIM software is a game-changer for airflow management. It provides real-time monitoring of temperature and airflow patterns, helping identify problem areas like hot spots. By visualizing thermal conditions, DCIM enables proactive adjustments, boosting cooling efficiency and system reliability.

What happens if airflow is disturbed?

If airflow in a data center is not maintained properly, several critical issues can arise, affecting performance, efficiency, and equipment lifespan:

-

Overheating of Equipment

Poor airflow leads to uneven cooling system, causing servers and other hardware to overheat. Overheating can result in frequent shutdowns, decreased performance, or even permanent damage to sensitive components.

-

Increased Energy Consumption

When airflow is not optimized, cooling systems must work harder to maintain desired temperatures. This leads to higher energy usage, significantly increasing operational costs.

-

Formation of Hot Spots

Inefficient airflow can create hot spots—localized areas of high temperature—resulting in inconsistent cooling. These spots are particularly dangerous as they may cause localized failures without triggering broader system alerts.

Read more: 8 Tips for a Successful Data Center Migration

-

Reduced Equipment Lifespan

Continuous exposure to improper temperatures strains hardware, reducing its operational lifespan. This accelerates the need for replacements and increases maintenance costs.

-

Poor System Reliability

Inadequate airflow management can compromise the reliability of the entire data center, causing unplanned downtime and affecting service delivery, which is especially critical for businesses relying on uninterrupted data access.

-

Environmental Impact

Inefficient cooling increases energy consumption, contributing to a larger carbon footprint. Over time, this undermines sustainability goals and compliance with environmental impact regulations. Proper airflow management ensures operational stability, energy efficiency, and hardware longevity.

FAQ

What are some common tools for monitoring data center airflow?

Tools like thermal imaging cameras, environmental sensors, and DCIM software help monitor airflow. These tools provide real-time data on temperature and humidity levels, enabling data center managers to optimize cooling and prevent inefficiencies.

Can poor airflow cause downtime in data centers?

Yes, inadequate airflow can lead to overheating, which may cause servers and critical systems to shut down unexpectedly. This downtime can disrupt operations, compromise data, and result in financial losses.

How often should airflow management strategies be reviewed?

Airflow management strategies should be reviewed periodically, ideally every 6–12 months. Regular reviews ensure that adjustments are made for new hardware, rack reconfigurations, or changes in cooling systems, maintaining optimal efficiency.